THE MAGAZINE OF THE GERMAN-THAI CHAMBER OF COMMERCE 2/2023 http://thailand.ahk.de GTCC Business Luncheon — “Thailand Economic Outlook 2023” GTCC Ordinary General Meeting 2023 Thailand prepares for green hydrogen ANNUAL PARTNERS 2023 PREMIUM PARTNERS 2023

GREEN HYDROGEN AND ALTERNATIVE ENERGY

Dear readers,

Thailand has set its climate goal to achieve carbon neutrality by 2050 and a net-zero target by 2065. Green hydrogen has entered the spotlight following Thailand’s efforts in using renewable energy.

Currently, most hydrogen in use in Thailand and the South-East Asia is not “green”, but “grey”. The grey hydrogen is utilised mainly in manufacturing processes, for fertiliser in agriculture, in methanol production, the steel industry, and in oil refineries. It is not generated by renewable energy and even increases carbon emissions. Thailand is switching to green hydrogen, which can be produced from all forms of renewable energy, including solar, wind, hydro, and geothermal.

To achieve its goal in green hydrogen transition, Thailand can learn from the German experience, including the strong strategy setting of the German government on the Energiewende (Energy Turnaround), and particularly the German National Hydrogen Strategy. Germany has also taken a market approach during the past few decades, such as liberalization of energy markets and the integration of European energy markets. German businesses use their skills and technologies to become pioneers of hydrogen technology.

German organisations and companies have already been supporting the development of green hydrogen in Thailand with their expertise. For example, GTCC in partnership with the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH supports the policy and market development for green hydrogen and Power-to-X through studies and training, public private partnerships (PPP), projects and collaboration with hydrogen specialists from Germany within the framework of the International Hydrogen Ramp-up Programme “H2Uppp” (BMWK). Enapter, a manufacturer of highly efficient AEM Electrolysers, currently partners with key players in Thailand, including Chiang Mai University (CMU). In partnership with GIZ and CMU, it implements the project “Making Chiang Mai a Knowledge Hub for Green Hydrogen”, which includes building a training facility at CMU for project developers to receive training on modular hydrogen systems. thyssenkrupp Uhde has developed proprietary solutions for flexible, safe and reliable production of green ammonia based on renewable energy sources. TÜV SÜD provides green hydrogen certifications based on the European Union’s renewable energy directive 2 (RED II) and the “fit-for-55 strategy”.

I trust you will enjoy an interesting and informative read.

Dr. Roland Wein

UPDATE is published quarterly by the German-Thai Chamber of Commerce (GTCC) and distributed through an electronic platform to members and qualified non-members in Thailand and abroad. It is also available on our website: thailand.ahk.de/en/publications.

Any opinions expressed in articles in this e-magazine do not necessarily reflect the views of the Chamber. UPDATE welcomes story and photo contributions from members and non-members alike. Articles may be reproduced with acknowledgement, except for those taken from other sources.

For inquiries, please contact: communications@gtcc.org.

Publisher/Editor-in-Chief: Editor & Communications Director: Design & Layout: Sub-Editor: Dr. Roland Wein Chadaphan Maliphan Sorapol Liengboonlertchai Tony

Oliver

FROM THE EDITOR

GREEN HYDROGEN AND ALTERNATIVE ENERGY

04 Thailand prepares for green hydrogen

06 Biofuel producers seek alternatives

08 Unlocking Thailand’s carbon-free future with green hydrogen

10 Sustainable ammonia solutions by thyssenkrupp Uhde

12 Germany supports Thailand’s policy and market development for green H2 and Power-to-X through the H2Uppp programme

16 Enapter aims to drive the growth of hydrogen infrastructure in the SE Asia region with partners in Thailand

CHAMBER ACTIVITIES

19 First GTCC AFTERWORK

20 GTCC visits Oerlikon Balzers Coating (Thailand) Co., Ltd.

21 DIHK/AHK Regional Workshop Asia-Pacific

22 GTCC Business Luncheon — “Thailand Economic Outlook 2023”

24 Thai-German conference on “Solar PV and Grid-Integration”

27 GTCC Ordinary General Meeting 2023

BUSINESS BRIEFS

28 Mercedes-Benz appointed new President and CEO of Mercedes-Benz Thailand

28 60 years anniversary of RIS Swiss Section –Deutschsprachige Schule Bangkok

29 DACHSER opens new office in Chiang Mai

29 Linde Material Handling Thailand Launches New Customer Experience Center (CEC)

GTDEE INSIGHT

30 PAL Final Examination, Part 1, in Automotive Mechatronics at BMW Training Center, Pathum Thani

31 Welcoming Dr. Kristina Heussner, Federal Ministry of Economics and Climate Action

MEMBERS’ CORNER

36 New GTCC members

TRADE FAIRS

38 EMO Hannover 2023 World Tour in Bangkok 40 BAU 2023

CONTENTS

41 DMEA 2023

42 ISEE & CEFE 2023 43 Insights-X 2023 44 AGRITECHNICA 2023

Thailand prepares for green hydrogen

Thomas Hundt

The first Thai demonstration plants are producing green hydrogen. Research and development are also underway.

Thailand has pledged to stop emitting net greenhouse gases by 2065. The Government's long-term strategy to reduce greenhouse gas emissions also includes the use of green hydrogen.

HYDROGEN CLUB SHOWS POTENTIAL APPLICATIONS

Stakeholders from the hydrogen sector joined together in 2020 to form a consortium, the Hydrogen Club, which holds webinars and symposia, and aims to build pilot plants. The club includes the national oil and gas company PTT, the state-owned power utility Electricity Generating Authority of Thailand (EGAT), the industrial gas producer Bangkok Industrial Gas, Toyota Motor Thailand, Toyota Daihatsu Engineering & Manufacturing, Mitsui Thailand. The club also includes the Department of Alternative Energy Development and Efficiency of the Ministry of Energy as well as the National Science and Technology Development Agency and the National Energy Technology Center (ENTEC) research institutes.

ENTEC is working on technologies for storing energy and has noticed an increasing interest in hydrogen and fuel cell technologies. The departments of process and energy engineering at Chulalongkorn and King Mongkut Universities in Bangkok are also conducting research on alternative energy, including hydrogen. The researchers have published several papers on hydrogen and fuel cell technology.

FIRST DEMONSTRATION PROJECTS PRODUCE GREEN HYDROGEN

EGAT opened the first pilot project in 2018 that produces and stores green hydrogen. The electrolyser for the Wind Hydrogen Hybrid Plant in Nakhon Ratchasima province was supplied by the Canadian company, Hydrogenics. A 300-kilowatt fuel cell supplies a centre

run by EGAT there, where visitors can learn about renewable energies.

Enapter, a manufacturer of electrolysers, the German Society for International Cooperation, and the Energy Research and Development Institute at Chiang Mai University announced in February 2023 that they will establish the first green hydrogen training centre in South-East Asia.

The training centre will offer hands-on courses for project developers, system integrators and energy professionals, and they will be able to study green hydrogen at a demonstration plant. This is the family home of Sebastian-Justus Schmidt, the founder of Enapter. His award-winning Phi Suea house in Chiang Mai, northern Thailand, features a self-sufficient solar power system with a hydrogen battery storage system and a hydrogen fuel cell.

HYDROGEN IN THE TRANSPORT SECTOR

PTT opened the country's first hydrogen filling station in November 2022. Two hydrogen vehicles from the Mirai series of

04 GREEN HYDROGEN AND ALTERNATIVE ENERGY

UPDATE 2/2023

Toyota are driven to the filling station in Pattaya for test purposes. Bangkok Industrial Gas supplies the hydrogen.

Thailand's CP Group and Toyota agreed in January 2023 to establish a joint venture that will produce hydrogen from animal waste. The hydrogen will power Toyota's lightweight fuel cell trucks, which CP plans to use as delivery vehicles.

HYDROGEN INDUSTRY EXISTS

Thailand has been producing gray hydrogen from gas or as a byproduct of refining.

According to the implementation arm of the Technology Mechanism of the United Nations Framework Convention on Climate Climate Technology Centre and Network (CTCN), four companies produce hydrogen for commercial customers.

Bangkok Industrial Gas describes itself as the largest producer of hydrogen, which it sells to industrial users. Other producers of hydrogen include Linde and Air Liquide.

PTT Global Chemical (PTTGC) also has a Hydrogen Manufacturing Unit and PTTGC's olefin plants produce hydrogen on the side. The capacities and quantities produced are not known.

HYDROGEN IN POWER PLANTS

EGAT announced in October 2022 that it would build a hydrogen-fuelled power plant. The 5-megawatt plant is to be built on the site of the Klong Luang gas-fired power plant in Pathum Thani province. Bloom Energy, a fuel cell manufacturer from the United States of America., was selected as the technology partner.

A subsidiary of EGAT, the Electricity Generating Public Company (EGCO), merged with the Japanese energy company JERA Asia in January 2023. JERA will provide solutions for generating electricity from hydrogen and ammonia. The alternative fuels are expected to complement gas and coal in power generation.

Global Power Synergy, part of the PTT Group, is also exploring the use of hydrogen and ammonia for power generation together with Avaada Energy from India. PTT also wants to lease two zero-emission oil tankers from the shipping company AET in Singapore that can use hydrogen as fuel.

PLANS, FUNDING AND REGULATIONS ARE STILL MISSING

So far, the activities are hardly coordinated. The CTCN is therefore commissioning a national hydrogen strategy and action plan. The authors are to write a paper that identifies opportunities for production, transport and use of green hydrogen. After all, Thailand has untapped renewable energy potential, large biomass resources, and would like to implement a sustainable circular bio-economy.

The Ministry of Energy has commissioned Chulalongkorn and Chiang Mai Universities to develop a roadmap for hydrogen development. The legal framework also still has to be created.

The German Federal Ministry of Economics and Climate Protection (BMWK) has been promoting green hydrogen in Thailand since 2022 as part of the International Hydrogen Ramp-up Programme (H2Uppp). Through the programme, knowledge and experience are shared and project ideas are identified.

Contact details:

Thomas Hundt

Director Thailand, Cambodia, Myanmar, Laos

GERMANY TRADE & INVEST

www.gtai.com

HYDROGEN AND

05

GREEN

ALTERNATIVE ENERGY

“ Stakeholders from the hydrogen sector joined together in 2020 to form a consortium, the Hydrogen Club, which holds webinars and symposia, and aims to build pilot plants.”

www.thailand.ahk.de

hydrogen tank in Thailand

Biofuel producers seek alternatives

Thomas Hundt

Demand for biodiesel and bioethanol will decline in Thailand in the medium term. In fact, producers are already looking at new alternatives.

Thailand was the world's seventh largest producer of biofuels in 2021. Converted into oil equivalents, it produced an average of about 40,000 barrels per day. Producers have increased their output fourfold since 2008.

The production volume would actually have to be doubled to 7.5 million litres of ethanol and 8 million litres of biodiesel per day, according to a 2018 national alternative energy plan. Domestic production covers the demand; Imports and exports do not play a role.

About two thirds of bioethanol is produced from molasses, a by-product of sugar production, and the rest from manioc. According to the Ministry of Energy, by the end of 2022, 27 bioethanol plants had a total capacity of 6.57 million litres per day (table 2).

Capacity, litres per day

Source: Department of Energy Business, Ministry of Energy, 2023.

SUCCESS STORY COMING TO AN END SOON?

The Ministry of Energy is drawing up new plans for alternative energies and assumes that less biofuels will be needed in the medium term. Sales of fuels for combustion vehicles could peak in 2027. Electric vehicles will also displace combustion vehicles in Thailand, experts say.

The Government has a target of 30 per cent of vehicles produced in Thailand being emission-free by 2030. It wants to reduce carbon dioxide emissions and make the country the production centre for electric vehicles in the region.

However, it is a long way to achieving a zero-emission vehicle fleet. At the end of 2022, 43.4 million motor vehicles were registered, of which only 32,081 were fully electric models.

Source: Department of Alternative Energy Development and Efficiency, Ministry of Energy, 2023.

06 GREEN HYDROGEN AND ALTERNATIVE ENERGY

Company

GGC

Bioindustrial Mitr Phol

Ubon

E85

Thai Agro Energy

UP Ventures

Mitr Phol

Kuchinarai

Table 2. Bioethanol producers in Thailand

KTIS 600,000

Biofuel 500,000

Bio Ethanol 400,000

385,000

350,000

340,000

Biofuel 320,000

Others 3,675,000

2018 2019 2020 2021 2022 Biodiesel 4.34 5.05 5.04 4.55 3.81 Bioethanol 4.07 4.46 4.04 3.64 3.91

Table 1. Biofuel production in Thailand (millions of litres per day on average)

UPDATE 2/2023

A government committee adjusts the blending rates of bioethanol and petrol, taking into account the supply of the two raw materials. In 2024, blends with 10 per cent ethanol (E10) and 85 per cent (E85) are to be phased out, and only E20 petrol will remain. Bioethanol sales volumes are expected to decline with the termination of E85.

BIOPLASTICS AS AN ALTERNATIVE

Some manufacturers now want to invest in new processes such as the production of bioplastics. For example, SCG Chemicals of Thailand and Braskem of Brazil, among the world's largest producers of biopolymers, are looking into investing in a bioethanol dehydration plant in Thailand to produce bioethylene and bio-based polyethylene.

PALM OIL FUELS BIODIESEL

Thailand has been producing biodiesel for blending into standard diesel since 2007. The manufacturers use palm oil as a raw material. About half of the palm oil harvest goes into the production of biodiesel.

The blending started at 2 per cent (B2) and was increased to 5 per cent in 2012 and 7 per cent in 2014. The Ministry of Energy introduced a 10 per cent blend (B10) and a 20 per cent variant (B20) for commercial vehicles in 2019.

The Government changes the blending ratios as needed to adjust biodiesel production to the available quantity as well as prices of palm oil. Harvest quantities fluctuate considerably, depending on weather conditions. However, B10 biodiesel is to be the only standard in the future.

The 15 producers have expanded their capacity from 8.5 million litres to 10.3 million

litres per day (table 3) since 2020, but were operating at less than 40 per cent capacity in 2022. Their biodiesel is consumed entirely domestically. Imports of biodiesel require a permit and do not play a role.

Aircrafts in Thailand consumed approximately 3.3 billion litres of JET A-1 jet fuel in 2022 and sales are expected to return to pre-Covid levels of more than 7 billion litres by 2024 at the lastest.

The international SAF market is also considered promising. The European Commission alone is planning SAF blending for fuel delivered to European Union airports. The minimum SAF shares are to be gradually increased from 2 per cent in 2025 to 63 per cent in 2050.

The International Civil Aviation Organization (ICAO) applies certain sustainability criteria to renewable biomass as feedstock for SAF within the framework of its Carbon Offsetting and Reduction Scheme for International Aviation. Feedstocks that are suitable for the production of foodstuffs should rather not be used. SAF from Thailand must meet these criteria in order to be certified.

*As of January 2023. Source: Department of Energy Business, Ministry of Energy, 2023

SWITCHING TO SUSTAINABLE AVIATION FUEL

The CO2 emissions of Thai air traffic are to be reduced. A working group of the Ministry of Energy is therefore developing guidelines for the production and sale of sustainable aviation fuel (SAF).

The joint stock company Bangchak announced in December 2022 that it wants to produce SAF from used cooking oil. The refiner is setting up a joint venture with biofuel producer BBGI and vegetable oil recycler Thanachok for this purpose. The plant is expected to have a capacity of 1 million litres of SAF per day and start operations by the end of 2024.

Companies in the PTT Group, the national oil and gas group, are also investigating whether they can produce SAF from esters, fatty acids or alcohol. The Thai company, Energie Absolute, wants to convert a plant that produces biodiesel to biofuels for aircraft. The new technology is to be implemented by the Swiss company Sulzer Chemtech.

Contact details:

Thomas Hundt

Director Thailand, Cambodia, Myanmar, Laos

GERMANY TRADE & INVEST

www.gtai.com

GREEN HYDROGEN AND ALTERNATIVE ENERGY 07 Table

Company Capacity, litres per day Global Green 1,927,962 Chemical Patum 1,800,000 Vegetable Oil New Biodiesel 1,300,000 BBGI Bio Diesel 1,000,000 AI Energy 722,222 Energy Absolute 650,000 PPP Green 630,000 Complex Others 2,230,000 Total 10,260,184

3. Thailand biodiesel producers*

“ Demand for biodiesel and bioethanol will decline in Thailand in the medium term.”

www.thailand.ahk.de

trucks loaded with sugar cane

Unlocking Thailand’s carbon-free future with green hydrogen

Bratin Roy

INTRODUCTION

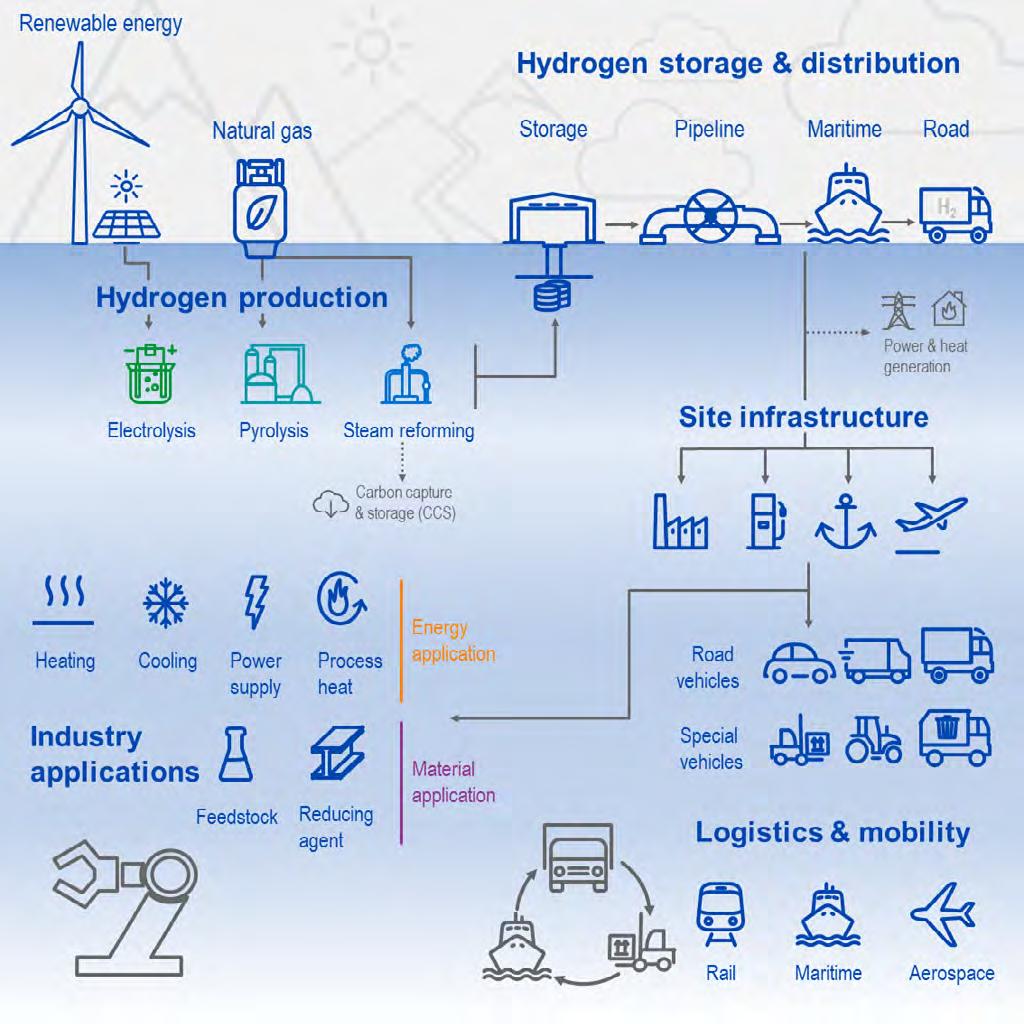

Hydrogen is set to play a central role in energy transformation as an energy storage medium and energy carrier. It will have a vital positioning as a key element to unlock a carbon-free future in global economy. There are different ways to produce hydrogen, which are typically referred to as green, blue, grey and sometimes turquoise, yellow and pink hydrogen.

When green hydrogen is produced, only renewable energy sources are used to provide the energy needed for hydrogen production, e.g., via electrolysis. Blue hydrogen is produced by splitting natural gas into hydrogen and CO 2 , for example, through steam methane reforming (SMR). The CO2 is not released into the atmosphere but is captured in the process and then stored in geological formation permanently. This process of carbon capture and storage (CCS) mitigates the environmental impact of CO2. It is important to note that grey hydrogen is produced, like blue hydrogen, from fossil fuels such as natural gas. However, carbon emissions are released into the atmosphere, making this way of hydrogen production less environmentally safe. Turquoise hydrogen is created through the pyrolysis of methane, which is split into solid carbon and hydrogen in a reactor. This process does not produce gaseous CO 2 as a by-product; if renewable energies power the reactor, it is considered CO 2 -emission neutral. Pink hydrogen is also made through electrolysis, with power coming from nuclear energy.

POTENTIAL FOR EXPANSION OF GREEN HYDROGEN USAGE AND THE RENEWABLE ENERGY INDUSTRY IN THAILAND

Thailand has pledged to achieve net zero emissions by the year 2065, with green hydrogen playing an important role in reaching

this target. Thailand intends to produce green hydrogen. Under the Alternative Energy Development Plan (AEDP), one of Thailand's five master plans related to energy development, hydrogen is included as part of the “Alternative Fuels” category with a set target goal of 10 kilotons of oil equivalent (KTOE) in total by 2036. For the green hydrogen, Thailand has a benefit of irradiation conditions that render solar power productive throughout the year. According to the International Energy Agency, given current baseload capacity,

08 GREEN HYDROGEN AND ALTERNATIVE ENERGY

UPDATE 2/2023

Thailand’s grid could still accommodate significant additional deployment of variable renewable energy to generate electricity.

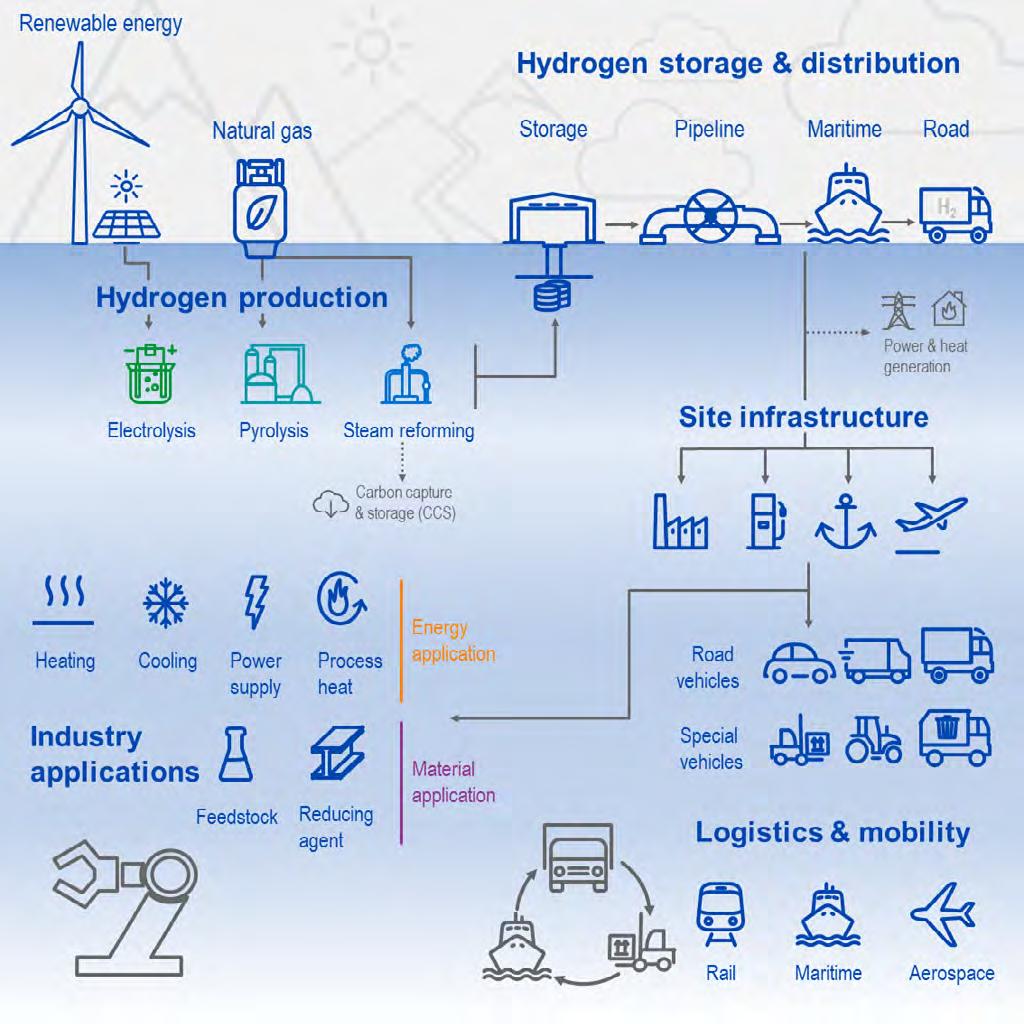

Thailand currently has an installed renewable energy capacity of more than 15 GW, and Thailand’s Energy Regulatory Commission started promoting power purchase agreements for up to 5.2GW across four types of renewable energy projects: 335 MW of biowaste; 1GW of solar with battery storage, 1.5GW from wind and 2.3GW of solar power without battery storage. It is aimed to have all the capacity that can be integrated into the production of green hydrogen installed by 2030. That green hydrogen can be used for several applications such as decarbonization of residential and commercial heating and cooling systems. In the mobility sector it can be used in hydrogen fuel cell vehicles, and hydrogen-based low carbon fuels can contribute to the decarbonization of the mobility sector as a feedstock to produce ammonia, methane and methanol.

CHALLENGES

Major challenges today are the cost of production as green hydrogen is a capitalintensive process, as scaling up of electrolysis cells is quite expensive as well as the high levelized cost of infrastructure and transportation. In addition, there are also safety concerns due to flammability, buoyancy and ability to embrittle metals of the hydrogen. Another major hurdle faced by the industry today in developing a hydrogen economy is the is complex and wide-ranging supply chain challenge. It includes: (a) utilities, providing either raw materials or

energy to enable hydrogen production, hydrogen manufacturing equipment and relevant supply chains; (b) transport, distribution and storage, including pipeline and vessel/vehicle transport; (c) fuel cell components and fuel cells; and (d) hydrogen carrier chemicals and materials. In addition, the lack of uniform standardization and international regulation synchronized with the absence of local requirement creates further uncertainty for investors, as the requirements of off-takers, especially from potential exporting countries, are still not very clear.

HOW TO OVERCOME THE ABOVE CHALLENGES

The current policy incentives mainly focus on the supply side. Developers and investors need a visible offtake pipeline for their product. Governments could provide this by introducing a green hydrogen consumption obligation (GHCO) mechanism for the production of fertilizer and other chemicals as well as petroleum refining, similar to the Renewable Purchase Obligations (RPO). Strong offtake agreements will make the projects bankable as well as

uniform certification schemes (like CertifHy, CMS70) for certifying hydrogen for onboard off- takers.

In addition, hydrogen’s future depends on large-scale CO2 storage, which can be provided by geological formations (such as aquifers, and depleted oil and gas reservoirs) to handle demand and supply changes. Research and development efforts are needed to increase the efficiency of the electrolyzer system as well as the electrolyzer operating time, power density and stack size. With these improvements, material costs will be reduced and more flexible systems achieved that can accommodate an occasionally interrupted and fluctuating power supply. Further additional revenue sources can be explored in the carbon market. Carbon markets are a mechanism by which carbon mitigation actions can be certified and transferred to tradeable carbon credits. Three different types of carbon markets which can be used for green hydrogen projects are National Carbon Markets, Voluntary Carbon Markets (int.) and Compliance Carbon Markets (Art. 6, PA).

Bratin Roy Sr. Vice-President Industry Service I Sustainability

Bratin Roy Sr. Vice-President Industry Service I Sustainability

TÜV SÜD ASEAN, South Asia, Middle East and Africa Region (ASMEA)

Contact Details:

Rishab Dudhoria

Business Development Head – ASEAN Supply Chain Services and Sustainability

TÜV SÜD (Thailand) Limited +66 65 985 3011

rishab.d@tuvsud.com

“

GREEN HYDROGEN AND ALTERNATIVE ENERGY 09

Major challenges today are the cost of production as green hydrogen is a capital-intensive process, as scaling up of electrolysis cells is quite expensive as well as the high levelized cost of infrastructure and transportation.”

www.thailand.ahk.de

Sustainable ammonia solutions

by thyssenkrupp Uhde

Karan Bagga

Ammonia’s use as an energy and hydrogen vector is gaining more and more attention in addition to its traditional use as a precursor for nitrogenous fertilisers. This new use is prompting the development of new technology features and plant set-ups for harnessing low carbon or renewable energy as well as transporting it and using it at locations with energy intensive needs.

Hydrogen can be produced by using renewable energy via water electrolysis, completely free of carbon dioxide emissions, thus providing the means of storing and transporting renewable energy. Being a key precursor for many chemicals, green hydrogen also offers the potential to enable deep decarbonisation in industrial sectors in which it is difficult to abate with direct electrification, such as industrial chemicals, fertilisers and steel manufacturing.

However, the molecular and thermodynamic properties of hydrogen make it economically challenging to store and transport it globally. This is where ammonia offers a much more promising substitute. It can be produced from green hydrogen and nitrogen from air, without any CO2 emissions. Ammonia can also be produced from natural gas or other fossil resources with technology adjustment that can avoid or reduce the CO2 emissions. It has a higher volumetric energy density

than hydrogen, which makes it an attractive medium for transporting renewable energy. At the destination, it can be used to recover hydrogen via cracking or used directly for a variety of important applications, such as low carbon fertiliser production (figure 1)..

Additional uses are also emerging such as fuel for stationary power generation (co-firing with coal and gas), and bunker fuel for marine transport. Last, ammonia is already traded worldwide in large quantities (around 19 million t/year; therefore, safe handling is an established global standard, and the infrastructure is already in place.

Today, 80% of the annual global production of ammonia goes into fertiliser production, but it has been shown that potentially its use as a renewable energy vector will dwarf this figure in the conceivable low emission future. Therefore, it is important to focus on developing methods for safe and economical production of green ammonia on a large scale.

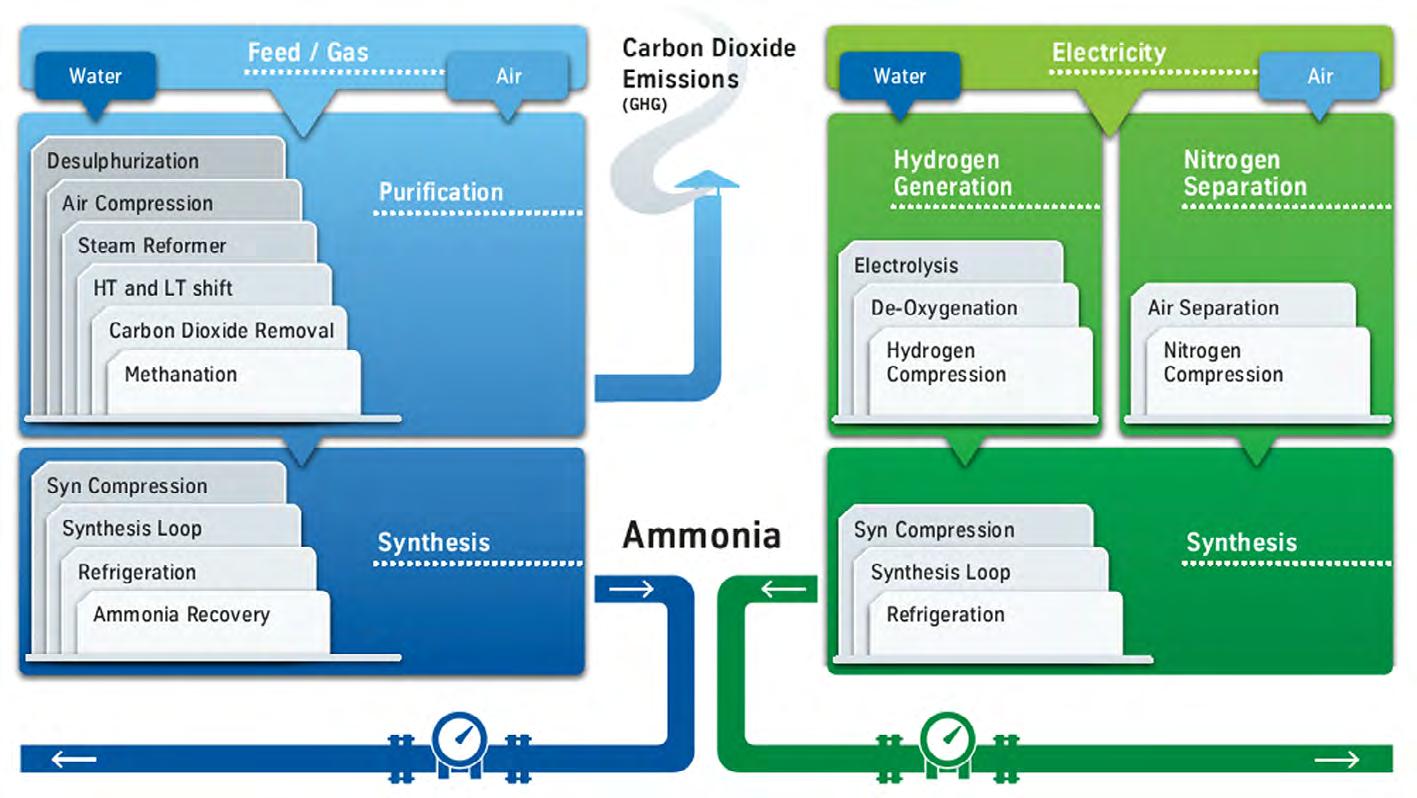

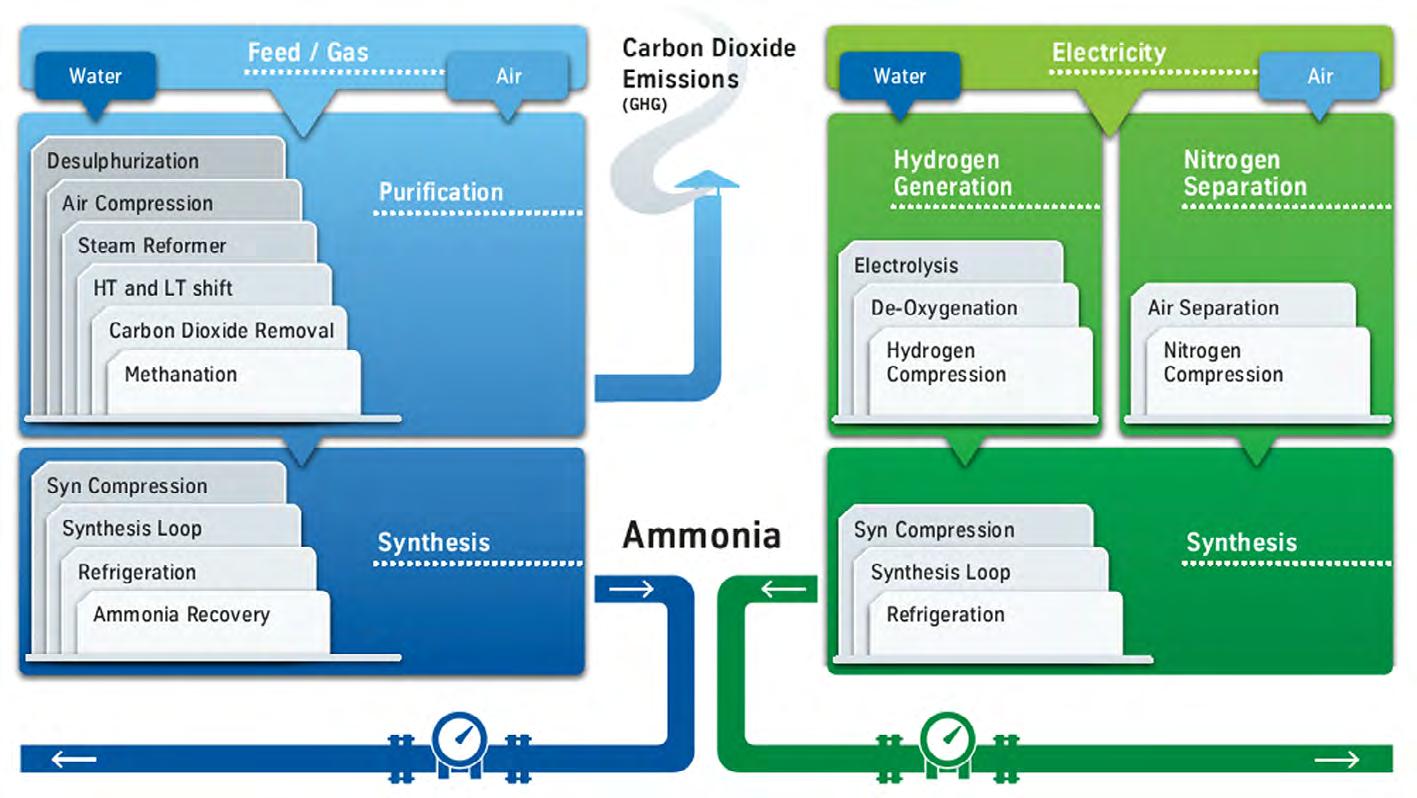

GREEN AND BLUE AMMONIA PRODUCTION

A green ammonia production facility produces hydrogen via the electrolysis of water

Figure 1. Ammonia value chain

Source: thyssenkrupp Uhde.

10 GREEN HYDROGEN AND

ALTERNATIVE ENERGY

UPDATE 2/2023

GREEN HYDROGEN AND ALTERNATIVE ENERGY 11

train green ammonia plant solutions in the range of 50 to 5,000 metric tons per day (mtpd). These plants can be customized to meet the specific needs of each customer, including modular systems that can be easily scaled up or down, depending on demand. On the blue ammonia front, thyssenkrupp Uhde also offers large-scale Steam Methane Reforming (SMR) and Autothermal Reforming (ATR) based plants with carbon capture.

using renewable energy. Green hydrogen then serves as a source for ammonia synthesis, together with nitrogen, which is cryogenically separated from the air in an Air Separation Unit (ASU). Ammonia synthesis as such is carried out according to the well-known HaberBosch-process. Further derivatives of ammonia, such as fertilisers, can be produced further downstream. Figure 2 compares a green ammonia production process with the conventional fossil fuel-based method.

For ammonia cracking, thyssenkrupp technology uses a proprietary catalyst system that allows for high efficiency and a long catalyst life, which reduces operating costs. The system also includes a heat recovery system that captures and reuses the energy generated during the reaction, further improving efficiency. The company’s optimized, well-engineered heat integration technology provides the highest ammoniato-hydrogen ratio, in order to deliver the standard of purity required to fulfil the requirements of the specific end-application.

Ammonia is set to play an increasingly crucial role in the energy transition of the South- East Asian region, both as a low emissions feedstock for the fertiliser and chemicals industries as well as a renewable energy vector. Its properties are conducive to affordable transport of large-scale transport of renewable energy.

Source: thyssenkrupp Uhde.

The CO2 emission can be reduced by capturing the CO2 and sending it to a sink. If the CO2 emission is largely reduced, this is referred to as “blue ammonia”.

AMMONIA CRACKING

Ammonia cracking is a chemical process in which ammonia (NH3) is broken down into its constituent elements, nitrogen (N2) and hydrogen (H2), usually by heating the ammonia in the presence of a catalyst. An ammonia cracking unit enables production of carbon-neutral green hydrogen for applications ranging from green steel and green chemicals to power generation and fuel. The properties of ammonia make it much easier and economical to transport compared to hydrogen, both in gaseous and liquid form.

THYSSENKRUPP UHDE'S SOLUTIONS IN THE AMMONIA VALUE CHAIN

Today, thyssenkrupp Uhde offers an integrated solution covering the entire renewable ammonia value chain, from production, storage and transport to reconversion back to hydrogen.

Focusing more on green ammonia production, thyssenkrupp Uhde offers modularised, single

thyssenkrupp Uhde has developed proprietary solutions for flexible, safe and reliable production of green ammonia based on renewable energy sources as well as large-scale blue ammonia solutions based on SMR and ATR technology. Finally, thyssenkrupp is developing a large-scale ammonia cracking solution which will become increasingly important in the region for supporting energy transition.

Contact details:

Karan Bagga

Chief Technology Officer

thyssenkrupp Uhde Australia

info@thyssenkrupp.com

https://www.thyssenkruppindustrial-solutions.com

“ Ammonia is set to play an increasingly crucial role in the energy transition of the South- East Asian region, both as a low emissions feedstock for the fertiliser and chemicals industries as well as a renewable energy vector.”

Figure 2. Conventional versus green ammonia production

www.thailand.ahk.de

Germany supports Thailand’s policy and market development for green H2 and Power-to-X through the H2Uppp programme

Tim Nees

Thailand has set ambitious climate goals to achieve carbon neutrality by 2050 and to accelerate the country’s energy transition. The decision-makers have acknowledged the need to enable a fast development of innovative energy solutions, such as hydrogen (H2), and want to position the country at the forefront of the energy transition in South-East Asia. However, much remains to be done to provide a sound knowledge and understanding of Thailand’s market opportunities and to steer its development. This awareness will be essential in equipping both Thai and German stakeholders with skills regarding green hydrogen production, transport, storage and use, and in setting up a framework conducive to both innovation and investments that will support green hydrogen (H2) and Power-to-X (PtX) market development.

Financed by the German Federal Ministry for Economic Affairs and Climate Action (BMWK), H2Uppp is therefore established in Thailand and implemented by the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH in partnership with the German-Thai Chamber of Commerce (GTCC). The objective is to support the policy and market development for green H2 and Power-to-X through: (a) studies and training (b) the identification and initiation of public private partnerships (PPP) and projects; and (c) the promotion and dissemination of knowledge through identification and connection of local and international H2 specialists, in particular vis-à-vis the German private sector. Mr. Tim Nees, H2Uppp Project Manager has shared with GTCC Update magazine the direction of the programme in Thailand and how Thailand could benefit from the lessons learnt by Germany.

Can you tell us about the specific goals and objectives of the H2Uppp programme, and how it aims to promote and support the development of green hydrogen and alternative energy in Thailand?

The aim of H2Uppp is to promote green hydrogen projects and market development, especially in developing and emerging countries, by leveraging innovative German and European technology know-how through partnerships with the private sector. The programme specifically supports the identification, preparation and implementation of pilot projects for the production and use of green hydrogen.

To achieve this goal, H2Uppp assists companies in Thailand in identifying project ideas and building networks with local stakeholders. The programme collaborates with private companies to jointly implement pilot projects as part of public-private

12 INTERVIEW

UPDATE 2/2023

partnerships along the value chain of green hydrogen. In addition, H2Uppp supplements market development with in-depth studies, multistakeholder dialogues and technical trainings.

What are the success factors for making green hydrogen widely adopted/available in Thailand?

Renewable energy: The key foundation for widely deploying green hydrogen is the expansion of renewable energy in Thailand. Only the use of additional renewable energy for green hydrogen production is sustainable. Currently, on-site hydrogen production without the long and expensive transport of the gas is the cheapest option.

Government: The Government can play a critical role in promoting the development of green hydrogen by providing adequate strategies, policies and a regulatory framework that encourages private sector investment. Financial incentives, tax breaks and subsidies can support the deployment of green hydrogen projects and accelerate market development.

Investment: Green hydrogen projects require significant investment, and private sector investment is crucial for enabling the industry to grow. Early learnings from pilot projects, government policies and international co-operation can create trust in the Thai market and attract investment.

Value chain and infrastructure: A robust infrastructure is necessary for supporting the production, transport, storage and distribution of green hydrogen. This includes production facilities, pipelines and storage facilities as well as infrastructure at harbours, industrial parks and other economic centres.

Skilled workforce: Hydrogen technology is complex, and a skilled workforce is needed to support its deployment. Newly qualified staff must be trained to become experts at handling hydrogen and hydrogen equipment.

Collaboration: Collaboration between industry, government and academia is critical for the successful deployment of green hydrogen. These entities can work together to share knowledge, develop technology and create a favourable environment for the industry. International co-operation is also necessary to support its widespread adoption. Thailand can work with other countries to acquire technologies, share knowledge and experience, co-ordinate research and development efforts, and promote the deployment of green hydrogen.

Awareness and education: The promotion of green hydrogen as a clean and sustainable energy source for the general public is essential. Awareness and education about its benefits and potential are important for its widespread adoption. The Government and private sector can work together to raise public awareness and educate the general public about green hydrogen.

Can you give an example of a project or initiative that the H2Uppp programme has been involved in which highlights its approach and impact in promoting green hydrogen and alternative energy in Thailand?

Public-private partnership between Enapter, ERDI (CMU) and H2Uppp (GIZ): This initiative aims to establish Chiang Mai as a “Knowledge Hub for Green Hydrogen”. The hub will focus on modular green hydrogen systems and feature a training centre offering both managerial and technical training as well as a demonstration site that will set a new standard for technology installation and certification in Thailand. Participants from companies involved in project development, energy service provision and industries with a demand for hydrogen will have the opportunity to learn directly from actual green hydrogen equipment and experience a fully functioning hydrogen system.

Study series: H2Uppp, in collaboration with DNV, produces a series of studies on H2 in Thailand, including the status quo globally and in Thailand, early policy and market instruments, and business potentials around green hydrogen. The studies aim to support the development of the Thai national hydrogen strategy (currently in the process of development by EPPO/MoEN) and inform relevant players from the public and private sectors to speed up the development of a green H2 market. Stakeholder dialogues are initiated based on the results of these studies.

PtX training: In 2022 H2Uppp organized trainings on green hydrogen and PtX for private and public stakeholders, and it plans to continue doing so in 2023. The training courses provide a comprehensive overview of the entire green H2 and PtX value chain, including the

INTERVIEW 13

www.thailand.ahk.de

opportunities of green H2 and PtX in future energy systems. After completing the training, the participants will be qualified to discuss and assess the potential production, application and trade of green H2/PtX products.

H2Uppp conference: H2Uppp, together with GTCC, organized the first H2Uppp conference on green hydrogen in Thailand in October 2022. The conference brought together about 200 public and private stakeholders to present, discuss and network about the current status of green H2 in Thailand and the next steps needed to advance the topic. The conference served as a platform to put green H2 on the agenda of decision-makers, allowed experts to network and express their opinions, and created the necessary platforms for B2G exchange and the building of a hydrogen value chain in Thailand.

How does the H2Uppp programme plan to support the development of public-private partnerships and projects in the green hydrogen and alternative energy sector in Thailand?

In collaboration with GTCC, H2Uppp covers the complete chain of project development for interested companies. This includes project scouting, sharing ideas on H2 projects with companies, supporting the creation of business consortia, project development, project management and project outreach.

Through the PPP instrument, H2Uppp can offer financial support to projects with a public benefit. The term "public benefit" refers to project results, such as demonstration/pilot projects, trainings, studies and improvements in regulatory frameworks that can be shared with other market participants.

In a PPP project, GIZ serves as the public partner, while the company serves as the private partner (such as in the PPP with Enapter). GIZ can co-operate with companies in two contractual constructs:

• Implementation agreement. In this type of agreement, GIZ provides up to 50 per cent of the project costs to the project partner, who then implements the project independently. The limit for the overall project volume is 400,000 Euros (with a maximum of 200,000 Euros from GIZ);

• Co-operation agreement. In this type of agreement, GIZ contributes up to 50 per cent, of the project costs and implements the project accordingly (mostly through contracting of services). The limit for the overall project volume is 4 million Euros (with a maximum of 2 million Euros from GIZ).

How does H2Uppp plan to mobilize networks of companies in Thailand and Germany to support the development of green hydrogen and alternative energy in Thailand?

H2Uppp engages in various activities, including conferences, business roundtables, trainings, bilateral meetings with companies, PPP projects, participation in external conferences, trade fairs, industry meetings, and exchange with associations such as the Thailand Hydrogen Club and other industry associations in Germany and Thailand.

What can Thailand learn from Germany’s success/lessons learnt in terms of green hydrogen development?

Sustainable energy transition: Germany aims to achieve a sustainable energy supply and is moving away from fossil fuels. Thailand can learn from the German

14 INTERVIEW

UPDATE 2/2023

experience, including the strong strategy setting of the Government of Germany on the Energiewende, and particularly the German National Hydrogen Strategy. Germany has also taken a market approach during the past few decades, such as liberalization of energy markets and the integration of European energy markets. Moreover, Germany's multi-stakeholder approach to finding consensus on the right steps for the Energiewende has received international acknowledgment.

Effective support policies and measures for market development: In order to become a leader in green hydrogen technology, Germany has brought forward and contributed to several pieces of strategy, legislation, and programmes at the European Union and national levels. This includes the German National Hydrogen Strategy, the European National Hydrogen Strategy and, just recently, the European Commission Delegated Act on Green Hydrogen. In terms of project support, Germany is involved in the IPCEI projects, the German Regulatory Sandboxes for green hydrogen projects, research funds as well as international support programmes such as H2Global, H2Diplo, H2Uppp, and the Funding Guidelines, to name just a few.

H2 Pilot Projects: Germany is pioneering the development of green hydrogen projects, including green hydrogen infrastructure, green hydrogen in steel production and chemical

processes, energy storage from renewable energy plants and e-fuel in transport (trucks, trains and aviation). Thai stakeholders can witness the progress, assess advantages and disadvantages of these projects, and learn to draw conclusions on a development pathway that is adequate for Thailand.

Technical know-how: In Thailand and South-East Asia, green hydrogen is still new, while Germany has hundreds of companies that work in the context of gas production, transport and applications. In particular, for the hydrogen industry, Germany is home to leading technology providers, including Linde, MAN ES, thyssenkrupp, Siemens Energy, Neuman and Esser, Enapter and Sunfire (to name just a few). Thailand can learn from their technical expertise and co-operate with these companies to develop projects in Thailand.

Risks and barriers: There are some barriers that can be easily identified from the German experience. This can help Thailand to leapfrog and overcome challenges quicker than other countries. This includes infrastructure development, policy and regulation, standards and certification, pilot projects and capacity development.

Contact details:

Tim Nees

H2Uppp (BMWK)

Project Manager

GIZ GmbH

tim.nees@giz.de

www.giz.de

INTERVIEW 15

“ In Thailand and South-East Asia, green hydrogen is still new, while Germany has hundreds of companies that work in the context of gas production, transport and applications[…] Thailand can learn from their technical expertise and co-operate with these companies to develop projects in Thailand.”

www.thailand.ahk.de

Enapter aims to drive the growth of hydrogen infrastructure in the SE Asia region with partners in Thailand

Tanai Potisat

Thailand is in the process of transition from fossil fuel-based energy to renewable energy, joining the global trend in tackling climate change. The Government has set its ambitious goal in striving to reach carbon neutrality by 2050 and a net-zero target by 2065. With increasing efforts in using renewable energy, green hydrogen has entered the spotlight. Although Thailand has not yet developed a substantial hydrogen industry, it has the potential to develop green hydrogen for domestic use and for export. Enapter, an innovative German company that manufactures highly efficient hydrogen generators – known as electrolysers – currently partners with many key players in Thailand, including an educational institution, as well as oil and gas companies.

UPDATE interviewed Mr. Tanai Potisat, SEA Business Development Manager at Enapter for an overview of the company and its collaborative projects with local partners. Prior to working at Enapter as Business Analyst in 2019, Mr. Potisat was Research Assistant at the Energy Research Institute, Chulalongkorn University in 2014 and later worked with the German development agency GIZ from 2015-2017 as Project Assistant and then as Junior Advisor. Tanai is eager to share the potential of green hydrogen, while also embracing realism about what green hydrogen can do.

Could you provide an overview of Enapter’s development in the green hydrogen and renewable energy sector in Thailand?

Enapter is a global company specialised in manufacturing of highly efficient, modular hydrogen generators using Anion Exchange Membrane (AEM) technology. Its origins can be traced back to 2004 when Mr. Sebastian-Justus Schmidt, a German software CEO, moved to Chiang Mai, Thailand, to be closer to clients. In 2015, he built a self-sustaining house that is powered with renewable energy. However, as solar power for the house is only generated

during the daytime, he looked for power storage for nighttime consumption. Hydrogen complemented with battery storage worked very well to ensure reliable power supply to the off-grid house. That's how the idea started, from the Schmidt family’s sustainable microgrid residence –the Phi Suea House – which became the world’s first self-sustaining, multi-house residence powered by a hydrogen-based clean energy system.

16 INTERVIEW

UPDATE 2/2023

Enapter was finally founded in 2017, spurred by the climate crisis and the power of hydrogen. Sebastian acquired ACTA and renamed it Enapter, which means “Energy Adapter” The company grew at a rapid pace, and in 2019 it opened a Berlin office and a new serial production facility in Italy. In 2020, Enapter launched the third-generation EL 2.1 AEM Electrolyser and hit the stock market with a reverse acquisition. Enapter’s commitment to sustainability and innovative technology has led to its recognition as the winner of the inaugural Earthshot Prize in 2021.

Enapter’s success continued in 2022 with the launch of its EL 4.0 next-generation AEM Electrolyser, as well as the opening of its Enapter Campus production and R&D site in Saerbeck, Germany and the expansion of its Pisa offices. In the same year, the company set a production record, delivering 1,200 EL 4.0 electrolysers to customers worldwide in the fourth quarter.With a strong focus on growth and R&D, Enapter is set to play a leading role in the transition to a clean energy future. Today, its electrolysers are used in more than 50 countries around the world.

What are the key challenges that Enapter faces in deploying green hydrogen technology in Thailand?

If you look at the current landscape of total energy consumption in Thailand, 20% is in the form of electricity and 80% is from other fossil-based sources. Although we are on a good trajectory with renewable energy in the electricity sector, there is no real viable or attractive pathway to replace oil, coal and gas with renewable electricity. Instead, we need a molecule like green hydrogen.

When companies with a decarbonisation agenda announce a carbon neutral or net zero carbon policy, they look to hydrogen as a pathway to reach their ambitious but crucial goals. We really need this energy portfolio for Thailand as a whole as well. What if we could produce our own clean fuel in the form of hydrogen by transforming electricity into green hydrogen? Hydrogen will come as a natural choice and eventually fuel fossil fields will become redundant.

The concerns for developing green hydrogen technology in Thailand are typical like with any incoming new technology. Let's say mobility. When you want to drive with a hydrogen fuel-powered car, what are the safety aspects? What are the regulations? What are the economics?

Enapter faces several key challenges in deploying green hydrogen technology in Thailand. One of these challenges is misconceptions about green hydrogen. Enapter’s approach to addressing this challenge is to spread awareness and knowledge about green hydrogen, and we believe that the growth of green hydrogen in Thailand will happen organically as a result of this.

Another challenge is the cost aspect, as other sources of energy such as fossil fuels are still cheaper. Enapter is attempting to tackle this challenge by focusing on production of its AEM Electrolysers at scale. This, combined with the inherent cost and performance benefits of AEM technology over competing electrolyser technologies will lower the cost of hydrogen production and make green hydrogen affordable.

In terms of Thailand’s green hydrogen industry, it is currently still in the early stages of development. Thailand has been utilising grey hydrogen for some time; however, the market for green hydrogen, has significant untapped potential. Green hydrogen can be

applied to three areas – energy, mobility and industry. Enapter believes that the growth of green hydrogen will continue to occur naturally as different sectors move towards global decarbonization

How does Enapter contribute to the development of a green hydrogen ecosystem in Thailand?

Enapter is contributing to the development of a green hydrogen ecosystem in Thailand through various initiatives. One key contribution is showcasing green hydrogen projects, such as the Phi Suea House in Chiang Mai, which allows people to see green energy in action.

Enapter is also partnering with organizations like Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH and Chiang Mai University on the “Making Chiang Mai a Hub for Green Hydrogen” project, which aims to spread knowledge, organize trainings and increase public awareness in green hydrogen. Through this partnership, Enapter is providing an open platform for green hydrogen capacity building and promoting a carbon-neutral mindset.

As interest in green hydrogen continues to grow in Thailand, Enapter’s efforts here are also beginning to include realizing highimpact hydrogen projects with partners, a step which is crucial in the development of a thriving green hydrogen ecosystem.

INTERVIEW 17

www.thailand.ahk.de

Please tell us more about your recent MoU signed with GIZ and Chiang Mai University.

We are a technology supplier with the hardware to efficiently produce hydrogen, and Chiang Mai University (CMU) has the facilities and people such as lecturers, researchers, and students for conducting research and disseminating knowledge. In partnership with GIZ and CMU, the project “Making Chiang Mai a Knowledge Hub for Green Hydrogen” includes building a training facility at CMU where project developers will receive training on our modular hydrogen systems. Chiang Mai is the perfect hub as participants will also visit Enapter’s Phi Suea House project to see green hydrogen in action.

Over the next two years, Enapter will conduct training activities for CMU at different levels –from basic to more technical – which will raise both professional skill levels and awareness of green hydrogen. As South-East Asia’s first hydrogen learning centre, it will enable the growth of hydrogen infrastructure in the region, promote regional co-operation and help position Chiang Mai and Thailand as pioneers in modular hydrogen technology.

Does Enapter have any plans or projects to increase production and scale up green hydrogen production in Thailand?

Although we are based in Thailand, our largest markets are in Germany, other parts of Europe, North America, Japan and the Republic of Korea. As for Thailand, we see considerable potential given the availability of renewable energy resources and its industrial base. That's why we work with key players in Thailand such as the main energy companies to make green hydrogen projects happen.

Enapter and the Electricity Generating Authority of Thailand (EGAT) signed an MoU back in August, 2019 to develop a Green Mini-Grid Sandbox Project at EGAT. That project has

successfully been realized at EGAT Learning Center, Bang Kruai, Nonthaburi. Here, ten AEM electrolyser units stand ready to receive visitors who are keen to learn about green hydrogen.

How far has Thailand’s green hydrogen industry been developed? Will Thailand be ready for the industry in the next 10 years?

Companies with carbon neutrality goals or companies with high CO2 emissions, might have some pressure to reduce their emissions thanks either to policies or common taxes. That could have an impact on how they see their business plan and how they want to decarbonize.

Is Thailand ready? Many companies are already showing interest, especially those in industries that already use grey hydrogen produced from natural gas, such as refineries or glass and steel manufacturers. Their consumption of grey hydrogen can be replaced with green hydrogen produced on site from renewables. That would be the simplest form and will come much fast than 10 years. Then other companies and industries who are not currently using hydrogen could come as a second wave.

Contact details:

Tanai Potisat

SEA Business Development Manager

Enapter Co., Ltd.

tpotisat@enapter.com

www.enapter.com

18 INTERVIEW

“ As for Thailand, we see considerable potential given the availability of renewable energy resources and its industrial base.”

UPDATE 2/2023

First GTCC AFTERWORK

We had a great time connecting with our members and partners at the first #GTCCAFTERWORK, which was also our first event of 2023, organised at Grand Hyatt Erawan Bangkok on 19 January 2023. More than 100 guests were welcomed by GTCC President Mr. Michael Welser with his opening remarks. On behalf of GTCC, he wished everyone happiness, prosperity and success in their businesses throughout the year.

For this year, we are grateful to have the support of our existing and new GTCC Premium Partners: B.GRIMM, DACHSER, Luther, Mazars in Thailand, RHENUS LOGISTICS and SCHAEFFLER, and GTCC Annual Partners: Bumrungrad International Hospital, GlueUp, and Lufthansa.

We also would like to thank our Event Partners Hampton Hotel & Residence Management and WHA Group for their support to this event, Beverage Partner Paulaner for the authentic German drinks,

and our Venue Partner, Grand

Erawan Bangkok for providing the perfect venue and delicious food and beverages.

GTRA Steering Committee meeting on sustainable mobility

GTCC, honorary member of the German-Thai Railway Association (GTRA), participated in a meeting held on 25 January 2023 at the German Embassy in Bangkok, together with the steering committee of GTRA, the Department of Rail Transport (DRT), the State Railway of Thailand (SRT), the Bangkok Mass Transit System (BTS), and experts in the industry. The discussion focused on enhancing the exchange on sustainable mobility, a field in which Germany possesses significant expertise.

CHAMBER ACTIVITIES 19

www.thailand.ahk.de

Hyatt

GTCC AFTERWORK in February

GTCC AFTERWORK event offered a wonderful time connecting with our members, partners and friends at Le Méridien Bangkok on 9 February 2023. Our President, Mr. Michael Welser, greeted a crowd of more than 90 attendees with a warm welcome and officially commenced the networking event.

We are very thankful to our Event Partners Luther, Mazars in Thailand, and Schüco for their invaluable support, Beverage Partner Paulaner by Flow Inter for supporting the authentic German drinks, and Venue Partner Le Meridien Bangkok for the beautiful venue and delicious cuisine.

We would like to extend our appreciation to all those who joined the event and made it such a memorable one.

GTCC visits Oerlikon Balzers Coating (Thailand) Co., Ltd.

On 17 February 2023, about 30 GTCC members had an opportunity to explore the production site of Oerlikon Balzers Coating (Thailand) Co., Ltd.

Thanks to Mr. Markus Lorenzini, Oerlikon President APAC, Mr. Michel Maeusli, Regional Lead – Tools APAC and General Manager Thailand and Vietnam, Mr. Gopinath Chikathor, Director – Sales and Operations of Oerlikon Thailand and the team for their warm welcome.

Located in Amata City Chonburi Industrial Estate, Oerlikon Balzers Coating (Thailand) Co., Ltd. specializes in providing tailored Surface Solutions in several fields of applications for all main industries, from various metal working industries to plastic manufacturing for future industries such as robotics, electric vehicles, medical appliances and aerospace. For more than 18 years the company has been serving more than 300 local customers.

Oerlikon is a leading global provider of surface and additive manufacturing solutions and services. The division offers an extensive portfolio of market-leading thin-film, thermal spray and additive manufacturing technology and equipment, components and materials.

20 CHAMBER ACTIVITIES

UPDATE

2/2023

Welcoming the Head of the Foreign Trade and Investment Promotion Department, Federal Ministry for Economic Affairs and Climate Action, to GTCC

It was a great pleasure to welcome Dr. Kristina Heussner, Head of Foreign Trade and Investment Promotion Department, Federal Ministry for Economic Affairs and Climate Action, Germany, at our office on 23 February, and to present GTCC’s key activities at an introduction meeting, The event was also joined by Mr. Johannes Kerner, Economic and Commercial Counsellor, German Embassy in Bangkok.

The meeting was followed by a productive lunch at The Peninsula Bangkok in which we also had the pleasure of welcoming Mr. Hans-Ulrich Südbeck, Deputy Chief of Mission, German Embassy in Bangkok and Mr. Thomas Hundt. Director Thailand, Myanmar, Cambodia, Laos of Germany Trade & Invest (GTAI).

DIHK/AHK Regional Workshop Asia-Pacific

Two-day DIHK/AHK Regional Workshop Asia-Pacific was hosted by GTCC during 23-24 February 2023 at Kimpton Maa-Lai Bangkok. The delegates of the workshop were welcomed by Mr. Benjamin Leipold, Managing Director of DIHK DEinternational GmbH, at the Sindhor. WE Kempinski Hotel Bangkok on 22 February. There were fruitful exchanges among the participants from the Association of German Chambers of Industry and Commerce (DIHK) and the German Chambers of Commerce Abroad (AHK) in Asia Pacific. The workshop was completed with a memorable farewell cocktail dinner with Ms. Jigger, Kimpton Maa-Lai Bangkok.

CHAMBER ACTIVITIES 21

www.thailand.ahk.de

GTCC Business Luncheon “Thailand Economic Outlook 2023”

About 100 participants joined the GTCC Business Luncheon "Thailand Economic Outlook 2023" on 2 March 2023 at the Sukhothai Hotel Bangkok. We owe a debt of gratitude to our Keynote Speaker, Khun Narit Therdsteerasukdi, SecretaryGeneral, Office of the Board of Investment (BOI) for sharing his insights on "Thailand 2023 and beyond: Toward an Innovative, Competitive and Inclusive New Economy”.

GTCC also would like to thank the panellists from GTCC member companies: Mr. Kanoksak Mokkamakkul, Executive Vice-President, Bangkok Bank Public Co., Ltd.; Mr. Alexander Donau, Regional Head, Asia-Pacific and Director of the Board for Leschaco (Thailand); Ms. Anlee Do, General Manager Thailand, Viet Nam, the Philippines and the Mekong Region, Lufthansa German Airlines; Mr. Jan Wittenstein, Head of Automotive Technologies Sales and Business Development SEA/P, Schaeffler Manufacturing (Thailand); and Mr. Tomasz Masur, Chief Executive Officer, Siemens Mobility; and our Moderator Dr. Timo Slawinski, Managing Director, Covestro (Thailand) for their kind contributions to the panel discussion.

Meeting with Minister of State, Federal Foreign Office, Germany

On 3 March 2023, GTCC had great pleasure in welcoming Dr. Tobias Lindner, Minister of State, Federal Foreign Office, and German Ambassador to Thailand Georg Schmidt for a meeting on Thailand’s economic development and activities of German companies in Thailand.

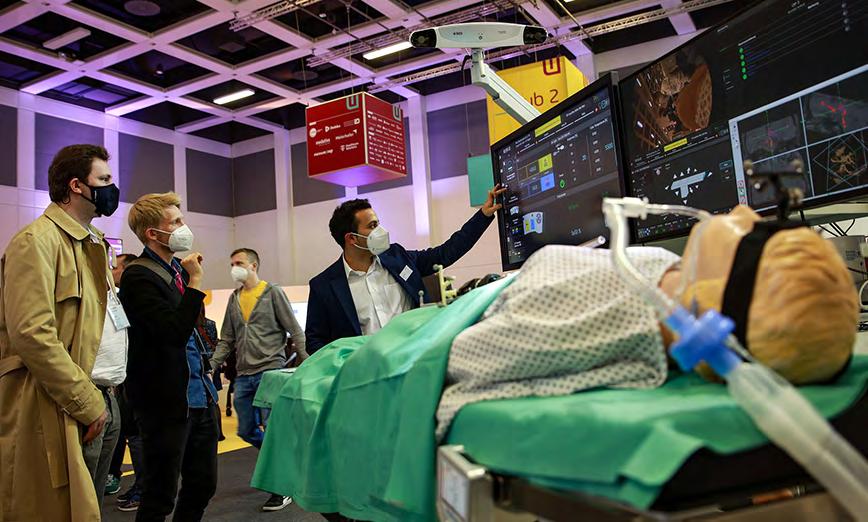

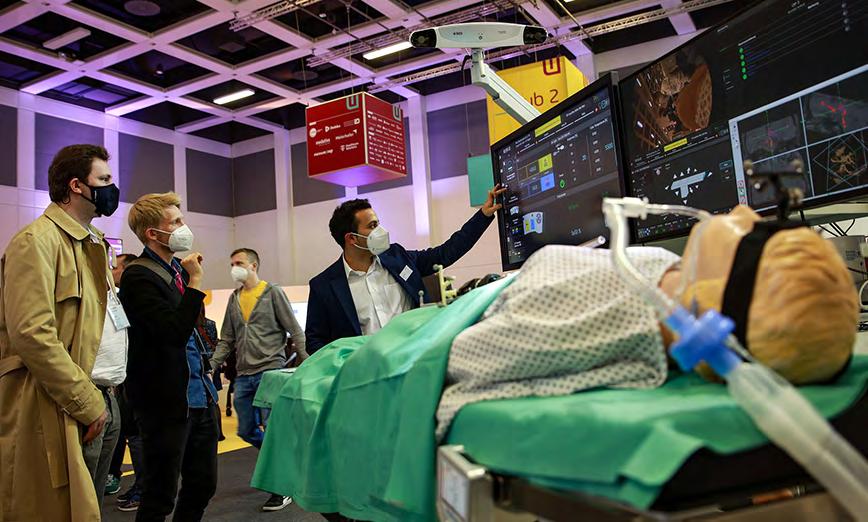

Representatives of GTCC member companies Mr. Martin Knoss, Robert Bosch Automotive Technologies (Thailand), Mr. Jan Wittenstein, Schaeffler Manufacturing (Thailand), Mr. Björn Bodenstein, Siemens Healthineers Thailand and Mr. Amir Reza Sinai, BEUMER Group (Thailand) discussed business opportunities and challenges in Thailand and ASEAN.

22 CHAMBER ACTIVITIES

UPDATE 2/2023

GTCC AFTERWORK Briefing with L&P

Our first GTCC AFTERWORK Briefing kicked off on 9 March 2023 with Lorenz & Partners (L&P) Co., Ltd. The briefing was organised at Kimpton Maa-Lai Bangkok.

Thanks to Mr. Till Morstadt, Managing Partner of L&P, for sharing his insights on "What Executives in Thailand need to know about International Tax Developments – An Overview on the Impact of BEPS, Pillar 2 and Minimum Tax on Investments and Investment Incentives in Thailand" with about 20 participants.

GTCC AFTERWORK in March

Third GTCC AFTERWORK networking was held on 9 March 2023. Thanks 100 guests for making our monthly networking event a wonderful gathering once again. We highly appreciate the generous support from our Event Partners G.M. Tour and Travel, Mazars in Thailand, and MedPark Hospital; Beverage Partner Paulaner by Flow Inter and Venue Partner Kimpton Maa-Lai Bangkok.

ACTIVITIES 23

CHAMBER

www.thailand.ahk.de

Thai-German conference on “Solar PV and Grid-Integration”

On 14 March 2023, a Thai-German conference on "Solar PV and Grid-Integration" was organised to provide a platform for discussing cutting-edge solutions for solar PV and grid integration necessary for Thailand's carbon neutrality 2050 goal, the projection for Thailand's new Power Development Plan (PDP) well as most recent advancements and pilot projects in Germany and Thailand.

More than 100 participants at the conference learned from keynote speakers and experts in the field including Mr. Johannes Kerner (German Embassy Bangkok), Mr. Tawatchai Sumranwanich (EGAT), Mr. Sarat Prakobchat (EPPO). The event also featured panel discussions joined by representatives from ERC, MEA, PEA and TPVA to elaborate on topics such as the potential for solar PV in Thailand, grid integration challenges, and innovative solutions for grid integration.

Participating German companies A.Eberle. GmbH & Co KG, Megger Germany GmbH, SMA Solar Technology AG and SolarNext AG showcased technology solutions.

The event was organised by GTCC in collaboration with the eclareon GmbH, as a further step to increase co-operation between Thai and German companies, and within the framework of the German Energy Solutions Initiative supported by the German Federal Ministry for Economic Affairs and Climate Action (BMWK). It was followed by a business-tobusiness matching on the following day.

GTCC Business Women Networking on “DigitALL: Innovation and technology for gender equality”

The first GTCC Business Women Network event of 2023 took place on 14 March 2023 at the Bangkok Marriott Hotel Sukhumvit. Speaker Khun Kulthirath Pakawachkrilers, CEO and Co-founder at Thailand e-Business Center (TeC) and President of the Thai E-commerce Association (THECA) and Master of Ceremony Khun Mookfee Nantanapramoth, CEO and Founder of Chris & M Co., Ltd. had a

fireside discussion on "DigitALL: Innovation and technology for gender equality" with about 50 businesswomen. GTCC thanks all participants, in particular Event Partner Bumrungrad International Hospital eclareon GmbH, Beverage Partner Serenity Wines Asia and Venue Partner Bangkok Marriott Hotel Sukhumvit for their great support to the event.

24 CHAMBER ACTIVITIES

UPDATE 2/2023

Online supplier seminar of the 2nd BMWK/BME Purchasing Initiative Southeast Asia

GTCC in cooperation with the German Association of Supply Chain Management, Procurement and Logistics (BME) and the Delegation of German Industry and Commerce in Myanmar organised the online supplier seminar of the 2nd BMWK/BME Purchasing Initiative Southeast Asia supported by the Federal Ministry for Economic Affairs and Climate Action (BMWK) on 15 March 2023. Over 45 participants were welcomed and gained insights into German buyers' decision-making and the B2B buyer's journey.

GTCC visits Ruwac Asia Ltd.

About 20 GTCC members joined GTCC Exclusive Site Visit to Ruwac Asia Ltd. On 17 March 2023. Thanks to Mr. Jens Peter Huhn, Managing Director; Mr. Thongkaow Silapachai, Regional Service Manager; Mr. Jimmy Khoo, Regional Sales Manager and the team for the warm welcome and the opportunity to explore Ruwac Asia's production site.

RUWAC, established in Melle, Germany in 1976, is the leading producer of customized industrial vacuums as well as dust collectors. RUWAC vacuums have been built In Thailand since 2009 by highly trained Thai craftsmen with quality components – sourced and certified by RUWAC Germany. Every RUWAC solution is customised to exactly suit the customer's requirement and to ensure long lasting quality and performance.

CHAMBER ACTIVITIES 25

www.thailand.ahk.de

Meeting with Member of the German Bundestag and European Policy Spokesperson of the CDU/CSU Parliamentary Group

GTCC members including GTCC President and Executive Director had a lunch meeting on 21 March 2023 with Mr. Gunther Krichbaum, Member of the German Bundestag and European Policy Spokesperson of the CDU/CSU Parliamentary Group in the German Bundestag, together with Dr. Carsten Buchholz, Head of Mr. Krichbaum's Office

and Dr. Céline-Agathe Caro, Director of Konrad-Adenauer-Stiftung e.V. Thailand. They exchange perspectives on economic developments in Thailand and Southeast Asia and a Free Trade Agreement between the EU and Thailand.

GTCC HR Briefing & Networking

About 40 HR professionals gathered at GTCC HR Briefing & Networking with a focus on "2023 Best Practices in C&B, ER, L&D and TA", organised on 23 March 2023 at Le Meridien Bangkok.

Thanks to our speakers Khun Ploytabtim Yeetho, Country HR Lead Thailand, Myanmar and Cambodia at Bayer Thailand; Khun Pachamon Panyosuk, Head of Human Resources Thailand and HR Business Partner Automotive Aftermarket, Southeast Asia at Schaeffler Manufacturing (Thailand) Co., Ltd.; Khun Suppawan Rattanapirom, Head of Business Services, Thailand & Vietnam at BASF (Thai) Limited; Khun Tikumporn Suewatanapong, Human Resources Lead at Robert Bosch Limited; and our moderator Mr. Tom Sorensen, Managing Director of Tom Sorensen Recruitment and NPAworldwide Co., Ltd. for sharing the insights into the topics.

26 CHAMBER ACTIVITIES

UPDATE 2/2023

GTCC Ordinary General Meeting 2023

The GTCC Ordinary General Meeting (OGM) 2023 was conducted on 30 March 2023 at Shangri-La Bangkok. We were honoured to welcome German Ambassador H.E. Georg Schmidt as our keynote speaker on "Thailand's way after the pandemic" .

The meeting was attended by 89 representatives of our German and Thai member companies from various industries. The elections of nine Board Members as well as the election of Vice President were conducted successfully.

GTCC congratulates the re-elected and newly elected Board Members. Mr. Michael Welser, Managing Director, Powertech 2004 Co., Ltd., who has been elected as GTCC President at the OGM 2022 for a two-year term, continues as the GTCC President for another year. Mr. Oliver Schnatz, Cluster General Manager, Sofitel Bangkok Sukhumvit has been elected as GTCC Vice President.

The newly elected Directors of the GTCC Board for 2023/2024 are as follows:

• Mr. Alexander Donau, Regional Head Asia Pacific and Director of the Board, Leschaco (Thailand) Ltd.;

• Ms. Do Van Anh Thu (Anlee), General Manager Thailand, Vietnam, Philippines and Mekong Region, Lufthansa German Airlines;

• Mr. Marcus Grundke, Managing Director, Rieckermann (Thailand) Co., Ltd.;

• Mr. Tomasz Marian Mazur, CEO, Siemens Mobility Ltd.;

• Mr. Kanoksak Mokkamakkul, Executive Vice President,Bangkok Bank Public Co., Ltd.;

• Ms. Van Nguyen, General Manager , Hormann Thailand Co., Ltd.;

• Mr. Oliver Schnatz, Cluster General Manager, Sofitel Bangkok Sukhumvit;

• Mr. Martin Schwenk, Managing Director MBC Region SEA 1 & CEO MBTh, Mercedes-Benz (Thailand) Ltd; and

• Mr. Michael Welser, Managing Director, Powertech 2004 Co., Ltd.

We would like to express our sincere gratitude to Mr. Volker Hellstern, who has resigned from the GTCC Board on 31 August 2022 and Mr. Roland Folger, who has resigned from the GTCC Board in December 2022; out-going Vice President Ms. Waranya Pratumtin, Sales and Marketing Manager, Thai Switchboard and Metal Work Co., Ltd.; and out-going Directors Mr. Andreas C. Richter, Managing Partner, Blumenthal Richter & Sumet Ltd. and Ms. Suwannee Singluedej, President & CEO at Siemens Ltd. Thailand for their strong commitment and consistent contribution.

CHAMBER ACTIVITIES 27

www.thailand.ahk.de

Mercedes-Benz appointed new President and CEO of Mercedes-Benz Thailand

engineer. After several functions in Quality and Finance at the MB Plant in Rastatt, Germany, he headed the Controlling department for the newly established Production Planning in Sindelfingen. From 2006 to 2015, he was in charge of different Finance and Controlling functions in South Africa, and Austria and as CFO of MBUSI in the United States.

Mercedes-Benz AG announced the appointment of Mr. Martin Schwenk as the new President and CEO of Mercedes-Benz (Thailand) Limited, succeeding Mr. Roland Folger who will take over a new position at Mercedes-Benz's headquarter in Germany, effective from January 1, 2023.

Mr. Martin Schwenk started his career in 1992 when he joined the 'Mercedes-Benz-Nachwuchsgruppe' in Stuttgart as a quality

On November 1, 2018, Mr. Schwenk took over as the Managing Director & CEO of Mercedes-Benz India. He played a key role in preparing Mercedes-Benz India for the future transition of the automotive industry, by driving electrification and digitalization initiatives. During his tenure, Mercedes-Benz India successfully mitigated the Covid-19 crisis, emerging stronger as a resilient organization. His vision, strategic collaborations, and deep engagement with people, partners and customers, enormously contributed to building a future-ready, transparent and highly people-centric organization.

Upon his appointment, the company is certain that Mr. Schwenk will drive business growth and lead Mercedes-Benz Thailand to achieve new heights in an exciting future of emerging mobility trends.

Source: https://www.nationthailand.com/business/pr-news/40019670

60 years anniversary of RIS Swiss Section – Deutschsprachige Schule Bangkok

The year 2023 marks the 60th anniversary of RIS Swiss Section as the only German-speaking school in Bangkok. The school community celebrated this milestone already on February 11 with a great party.

GTCC Executive Director Dr. Roland Wein participated at the special celebration together with several other guests of honour including H.E. German Ambassador Georg Schmidt, GTCC members and friends.

Founded in 1963, RIS Swiss Section – Deutschsprachige Schule Bangkok is the only international school in Thailand with a curriculum based upon the authentic values of Switzerland, Germany and Austria.

The first language of instruction at the bilingual, German-English school is German. Supplementary language support enables children from non-German-speaking backgrounds to enter at preschool and primary school level. Graduates of grade 9 (Hauptschule), grade 10 (Realschule) and grade 12 (Bilinguale Matura) receive official Swiss and German school leaving certificates. The school is situated on the 82,000 sqm campus of RIS in Bangkok’s eastern district of Minburi, combining a family-like atmosphere with world-class facilities.

The new school year 2023/24 will start on August 7. For more information, contact RIS Swiss section through its online platform https://ris-swiss-section.openapply.com/

28 BUSINESS BRIEFS

UPDATE 2/2023

DACHSER opens new office in Chiang Mai

International logistics provider DACHSER opens a new office in Chiang Mai, Thailand, to serve growing demands from local customers. The latest office opening will reinforce DACHSER’s position to deliver outstanding services to the electronics, fashion and sports, and food industries in the northern part of Thailand.

“DACHSER Thailand has had strong growth in recent years. The latest opening in Chiang Mai will support our growth strategy in the country. We are dedicated to providing cutting-edge, efficient, and technology-driven logistic solutions for the customers in the northern part of Thailand,” said Jesper Larsen, Managing Director Air & Sea Logistics South East Asia.

Supranee Junprachoo, Business Development Manager in Chiang Mai added: “Chiang Mai houses a number of companies from key industries, including electronics, fashion and sports and food. With industry expertise, DACHSER strives to offer customized solutions with excellent customer services, coupled with our wellestablished global network.”

In addition to Bangkok, Suvarnabhumi International Airport and Laem Chabang, the Chiang Mai office is DACHSER’s fourth location in Thailand. The expanded footprint puts DACHSER in a strong position to serve the Thailand market.

The logistics company is accelerating business growth in the South East Asian region. Apart from Chiang Mai office, another new office in Da Nang, Vietnam is also now in service.

Linde Material Handling Thailand Launches New Customer Experience Center (CEC)

Linde Material Handling Thailand is pleased to announce the opening of the new Customer Experience Center (CEC) in Bangna -Trad Road, Bang Saothong, Thailand. This is in addition to the Northern Bangkok HQ in Pathum Thani and the Eastern Seaboard branch.

Bangna area has seen strong growth in warehousing space and customer base for Linde Material Handling in Thailand. This CEC will allow sales team to showcase their products and solutions. In addition, the service team will be able to response our customers' needs in a shorter time frame.

The new CEC will be equipped with test drive area, showroom for new and used equipment and a dedicated facility for classroom training.

The opening ceremony was held on 11 November 2022, witnessed by Mr. Nino Pala, Senior VP of KION ITS APAC-RAPAC (Rest of Asia Pacific) and Mr. Tee Seng Chuan, Managing Director of KSAS (KION South Asia).

"KION Group is committed to growing our Industrial Trucks and Services (ITS) business in Thailand, and this Linde Material Handling Thailand CEC is a positive step in fulfilling that commitment to our customers in Thailand", said Mr. Nino Pala.

"The opening of this CEC in Thailand is an important step in expanding our market coverage and in providing greater customer experience in both sales and service for the growing Thailand material handling market", said Mr. Tee Seng Chuan.

BUSINESS BRIEFS 29

www.thailand.ahk.de

PAL Final Examination Part 1 in Automotive Mechatronics at Mercedes-Benz (Thailand) Training Centre, Samutprakarn

GTDEE/GTCC organised the PAL Final Examination Part 1 (Practical and Theoretical) in Automotive Mechatronics during 9-12 January 2023 for the Mercedes-Benz Apprenticeship Programme batch 2021. Led by GTDEE Project Director, Mr. Markus Hoffmann and Senior Project Manager, Dr. Kamonsak Suradom, the examination took place at the Mercedes-Benz Competence Centre at Bangna-Trad km. 19, Samut Prakan. The Examination Committee comprised experts from the College of Industrial Technology at King Mongkut's University of Technology North Bangkok as well as an independent examiner from the private sector.

PAL Final Examination, Part 1, in Automotive Mechatronics at BMW Training Center, Pathum Thani

GTDEE/GTCC organised the PAL Final Examination Part 1 for the BMW Service Apprentice Programme batch 2021 on 23-26 January 2023 at the BMW Group Thailand Training Center, Pathum Thani Province. The examination was held in accordance with German dual vocational education and training (VET) international (level A) standards. The Independent Examination Committee, made up of experts from the Automotive Engineering Department, the College of Industrial Technology, King Mongkut University of Technology North Bangkok (KMUTNB), GTCC and independent experts, ensured a fair and accurate assessment for all apprentices.

30 GTDEE INSIGHT

UPDATE 2/2023

Co-hosting a roundtable meeting with the Construction Training Center of Nord Rhein Westfalen (NRW), Germany

On 3 February 2023, GTCC/GTDEE and the Construction Training Center of NRW hosted a roundtable meeting at the Avani Riverside Bangkok Hotel, to discuss and explore co-operation opportunities in vocational education and training between VET institutions and higher education institutions in Thailand. Representatives of 15 organisations from the industrial, vocational education and university sectors attended the meeting, which started with welcoming remarks from Dr. Bozkurt of Berufsför derungswerk der Bauindustrie NRW (BFW) and Ms. Regina Kimpel of the German Embassy in Bangkok. Overall, the roundtable meeting was an important platform for exchanging ideas, knowledge and insights, and it paved the way for future collaboration in the field of vocational education and training.

Welcoming Dr. Kristina Heussner, Federal Ministry of Economics and Climate Action